Newsroom

Arnold Packaging Grows Automation Division, Adds Kevin McHenry as Automation Engineer as Part of Continued Investment in Industry 4.0

McHenry to Design Custom Automation Solutions and Integrate with Arnold Automation’s Robotics Platform

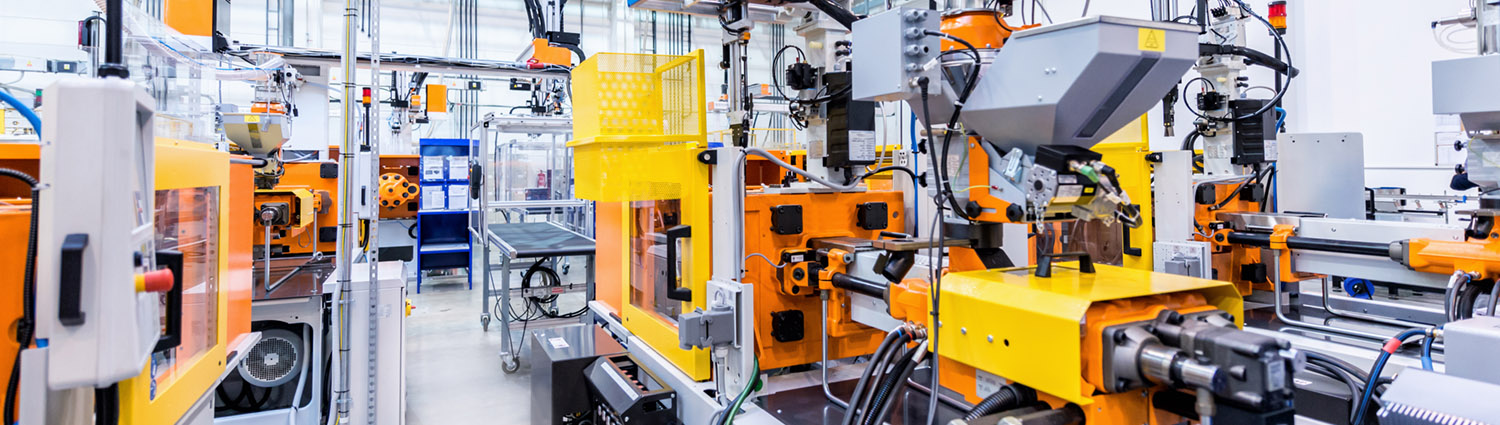

Baltimore, Md. — Arnold Packaging, the 85-year-old comprehensive packaging company, has hired Kevin McHenry as an automation engineer in the company’s Arnold Automation division. Arnold Automation, whichlaunched in July 2017, is exclusively focused on helping customers leverage automation to reduce labor costs and increase profitability. In his new role, McHenry, a 20-year mechanical engineering veteran, will help manufacturers and distributors exponentially increase productivity and efficiency through the design of custom equipment and systems.

“At Arnold Packaging, we’re known for providing innovative, custom packaging solutions that increase profitability through productivity. With Kevin’s expertise in 3D design, engineering and manufacturing we’ll bring the same level of innovative thinking and output to our automation clients who are focused on labor costs. We’re excited to have him on board as we continue to invest in industry 4.0 and develop equipment and robotic solutions that make automation a profit point,” said Mick Arnold, president of Arnold Packaging.

In September 2017, Arnold Automation signed the first-ever distribution deal with READY Robotics to distribute the TaskMate, a flexible automation platform that can be easily programmed to perform repetitive tasks. In his new role, McHenry will be designing complex systems that can integrate the TaskMate with customers’ existing equipment. He will also be expanding Arnold Automation’s offerings by designing custom automation solutions where the TaskMate is not a fit.

Previously a research and development manager at Better Engineering, McHenry specializes in 3D design, manufacturing and project management. Over the course of his career he became known for developingand expanding new product lines, as well as manufacturing industrial aqueous washing equipment for customers across a variety of industries. Most notably, McHenry designed a 30,000-pound capacity washer with a 15-foot diameter turn table — the largest weight capacity washer ever built at Better Engineering.

McHenry earned his Bachelor of Science in biomedical engineering with a concentration in mechanical engineering from Rensselaer Polytechnic Institute.

For more information about Arnold Automation, visit: arnoldautomation.com.

About Arnold Packaging

Founded in 1933, Arnold Packaging is the most comprehensive packaging company in the industry serving as a single source for the distribution of packaging supplies, the design and manufacturing of custom-made containers, automated inventory management and packaging automation. The company utilizes four generations of packaging expertise to provide innovative solutions that make its customers more profitable through individualized solutions, reduced freight costs, cutting edge packaging and shipping technologies, and more. Arnold Packaging’s new division, Arnold Automation, focuses exclusively on showing customers how they can leverage automation to bring down labor costs and increase profitability. www.arnoldpackaging.com