Get Profitable with Packaging

Reduce Freight Costs

The three largest variable costs for a shipping operation are freight, labor and packaging materials. Our studies indicate that freight averages about 47% of those costs with labor accounting for 46% and materials only 7%.

With many ecommerce companies offering free returns, freight is quickly increasing as a percentage of total variable cost. The most effective ways to reduce freight costs are to make the package lighter, smaller or reduce the number of packages you are shipping.

Most freight costs are determined by the weight of the package. As the package gets heavier, the cost to ship increases. Whether its parcel shipments (like UPS or FedEx) or less than truckload (LTL) shipments, heavier packages cost more to ship.

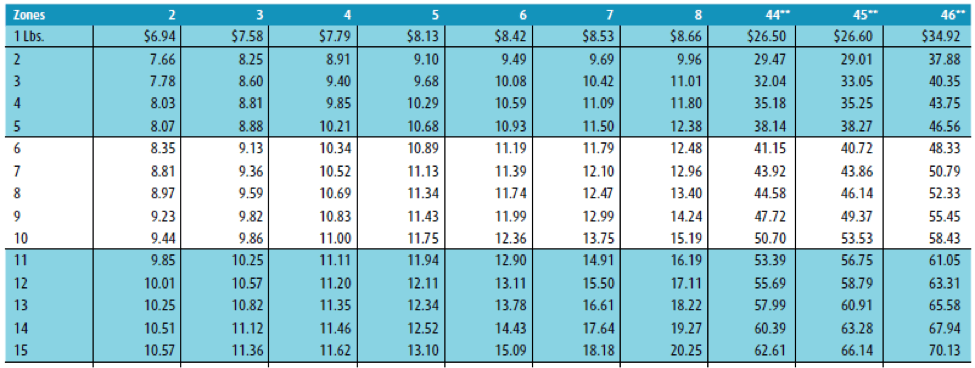

Generally, each shipment has a fixed cost associated with the shipment and then increases incrementally with each additional pound. The chart below shows the typical billing structure for parcel packages:

While we can’t always control the weight of the actual product, we can give every consideration possible to keep the packaging as light as possible while not sacrificing performance or increasing damage.

In addition to actual weight, all shipments are subject to dimensional weight. Dimensional weight is calculated by taking the outside dimensions of the box and dividing by 139. For example, a box that is 12” x 12” x 12” when divided by 139 would have a dimensional weight of 12.4 lbs. which rounds up to 13 pounds. Therefore, if your product and packaging actually weighs 8 pounds, you will be charged for 13 pounds.

The price increase in the chart above to zone three (middle of the USA) indicates a price difference of $1.25 per package. If you are shipping expedited service such as next day air, the difference is $11.78.

The final way to reduce freight is to reduce the number of packages you are shipping. If your shipments tend to have multiple packages, simply unitizing (tying them together) them will reduce the freight charge. For example, if you are Crayola and shipping two cases of sidewalk chalk to a school via UPS, connecting the packages with tape or strapping will reduce the freight. Instead of paying for two five-pound packages, you would be charged for one 10 pound package. The rate chart above shows a savings of $7.62 simply by shipping one package.

Our packaging professionals have the tools and talent to assess your individual needs and recommend the right solution to return valuable profitability to your operations. Ready to reduce your freight cost? Contact ARNOLD PACKAGING today. Or call us directly at 855-276-6537.

Get In Touch

Interested in reducing your freight cost?

More Productivity Tools

No-Cost Packaging Analysis